DTF PRINTING

What is DTF Printing?

DTF, or Direct-To-Film, is a modern printing technique that involves transferring high-quality images onto a special PET film. This film, known as a DTF transfer, is then heat-pressed onto various substrates, creating vibrant and durable designs.

Key Benefits of DTF Printing:

- Versatility: DTF transfers can be applied to a wide range of materials, including fabrics, plastics, wood, and more.

- Durability: DTF prints are known for their exceptional colorfastness and resistance to fading, cracking, and peeling.

- High-Quality Images: The DTF process produces crisp, detailed prints with a wide color gamut.

- Fast Turnaround: DTF printing offers quick production times, making it ideal for on-demand applications.

- Cost-Effective: While DTF printing may have a higher upfront cost compared to some other methods, it can be more cost-effective for large-scale production runs.

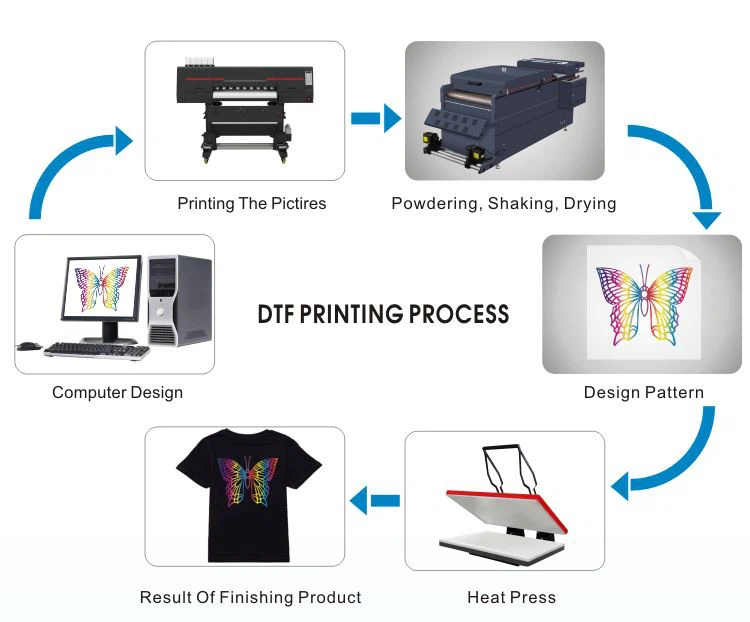

How Does DTF Printing Work?

- Image Preparation: A digital design is prepared and sent to the DTF printer.

- Printing: The design is printed onto a special PET film using specialized DTF inks.

- Powder Application: A layer of powder is applied to the wet ink to create a solid base.

- Curing: The film is cured in a heat press to set the ink and powder.

- Transfer: The cured DTF transfer is applied to the desired substrate and heat-pressed again to bond the design.

DTF Printing vs. Other Methods:

- Direct-to-Garment (DTG): DTF offers greater versatility in terms of substrate compatibility and often produces more vibrant colors, but DTG can be more cost-effective for smaller quantities.

- Screen Printing: While screen printing is ideal for large-scale production, DTF offers more flexibility for complex designs and shorter turnaround times.

- Sublimation Printing: Sublimation is primarily used for polyester-based fabrics and requires a specialized transfer process, while DTF can be applied to a wider range of materials.

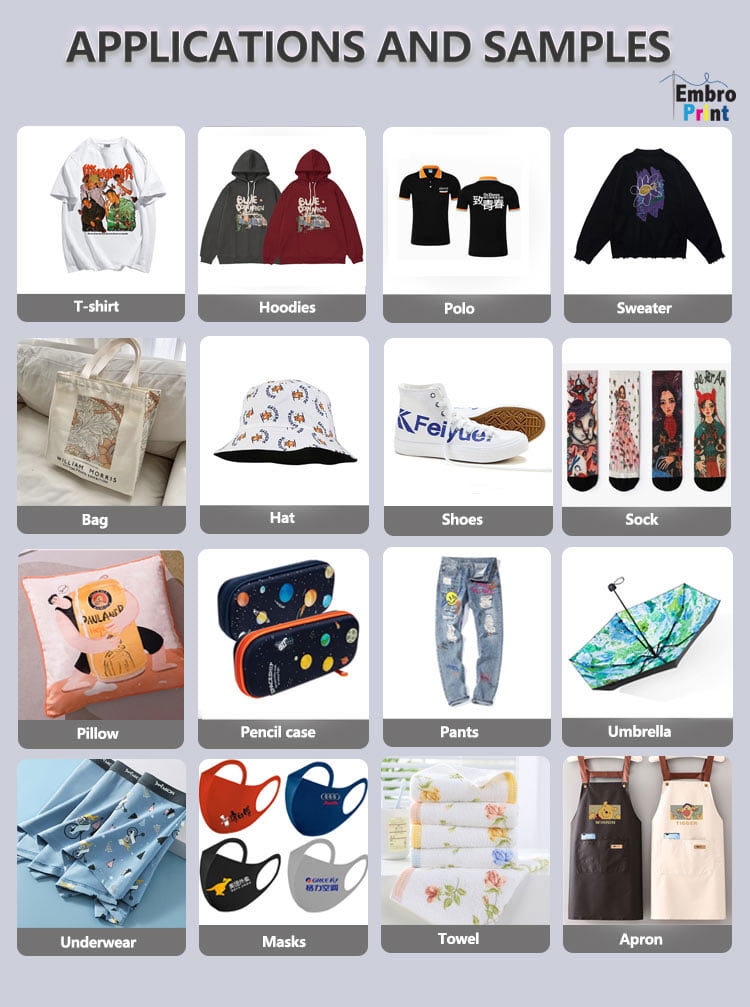

Applications of DTF Printing:

- Apparel: T-shirts, hoodies, hats, and accessories

- Home Decor: Pillows, blankets, wall art, and mugs

- Promotional Items: Bags, phone cases, and keychains

- Industrial Applications: Labeling, packaging, and product customization

Conclusion:

DTF printing has emerged as a leading technology in the printing industry, offering exceptional quality, versatility, and efficiency. Its ability to produce vibrant, durable designs on a wide range of substrates makes it a popular choice for businesses and individuals seeking custom printing solutions.