PAD PRINTING

What is Pad Printing?

is a specialized printing technique that utilizes a silicone pad to transfer ink onto a variety of surfaces. This method is particularly effective for printing on curved or uneven surfaces, making it ideal for promotional items like pens, mugs, and other three-dimensional objects.

Key Benefits of Pad Printing:

- Versatility: Can print on a wide range of surfaces, including curved, uneven, and three-dimensional objects.

- Durability: Prints are highly durable and resistant to fading, scratching, and peeling.

- Precision: Offers precise and consistent printing, even for intricate designs.

- Cost-Effective: Can be cost-effective for high-volume production.PA

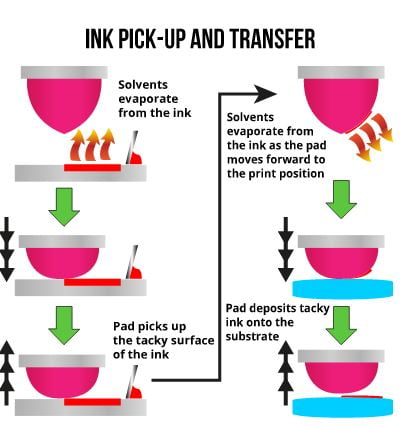

Here’s a breakdown of the pad printing process:

- Image Preparation: The desired image or design is created digitally and transferred onto a photopolymer plate.

- Ink Application: Ink is applied to the photopolymer plate using a roller.

- Pad Transfer: The silicone pad is pressed onto the inked plate, picking up the ink.

- Impression: The pad is then pressed onto the substrate (the surface to be printed). The ink transfers from the pad to the substrate.

Common Applications of Pad Printing:

- Promotional Items: Pens, mugs, USB drives, keychains, etc.

- Medical Devices: Labels, markings, and logos on medical equipment.

- Consumer Products: Appliances, toys, and electronics.

- Industrial Products: Parts, components, and tools.